AUSTROWATERTECH’S SERVICES

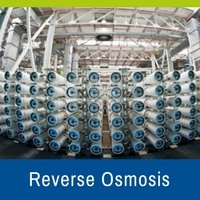

OUR TECHNOLOGY SOLUTIONS

Wastewater Treatment technologies from Austro Water Tech results with a high quality water solutions for all types of applications.We Offer a wide array of rugged,reliable and proven treatment solutions. The Water treatment technologies include Aerobic, Aerobic Treatment, Chemical Treatment, Gas Chlorination, Filtration System, Micro & Nano Filtration. As a solution provider we will select the right water treatment method for your project.

Austro’s Advanced Technology Solutions for Potable Water – There are water treatment systems will only make water potable without enhancing the quality. We, at Austro Water Tech do not just producing or promoting a technology developed by ourselves.Through our expertise and extensive network we have developed and created access to many innovative and the most suitable technical solutions. At Our best we have also consulted to match right technologies to right clients.

Our Key Points to Choose : Our advanced industrial water treatment solutions take a comprehensive, integrated, end-to-end approach to the water treatment needs, providing our clients with a one-stop-shop and a full process guarantee. We provide reduced installation time, with increased availability through flexible system design.

COUNTRIES SERVED

India

Japan

Bangladesh

Ethiopia

Indonesia

INDUSTRIES SUPPORTED

| Textile Processing | ||||

| Spinning | Washing | Washing-Denim | Dyeing & Washing | Garment |

| Weaving | Washing & Bleaching | Dyeing | Dyeing-Denim | Mercerising |

| Bleaching | Washing & Printing | Dyeing & Bleaching | Dyeing-Garment | |

| Printing | Printing & Dyeing | Printing & Washing | Dyeing & Printing | |

| Other Industries | ||||

| Auto Parts | Bottle Washing | Coconut Washing | Enzyme Effluent | Institutions |

| Banquet Hall | Carbon Washing | Drinking R. O. | Humidification R.O | Pharma |

No Comments

Sorry, the comment form is closed at this time.